The Rising Importance of Machine Blade Maintenance in the Poultry Industry

Machine Blade Maintenance for the Poultry Industry

Why Blade Maintenance Matters in Poultry Processing

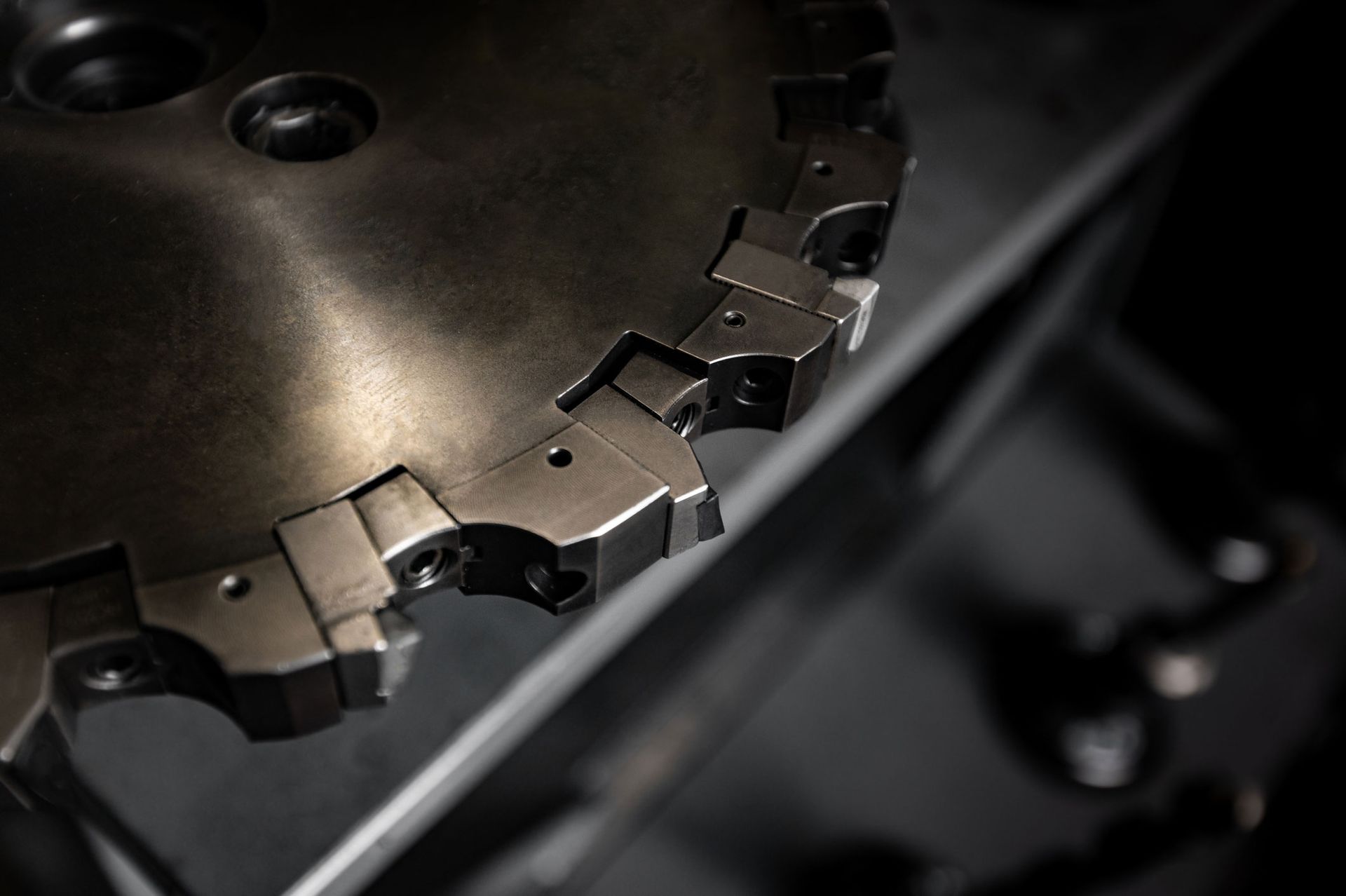

Machine blades are at the heart of poultry processing—handling tasks like deboning, portioning, trimming, and slicing. When blades lose their edge or become damaged, it doesn’t just reduce efficiency; it affects every part of the production line. Poorly maintained blades can lead to:

- Inconsistent cuts that compromise product presentation and yield.

- Increased waste, as meat is torn instead of cleanly sliced.

- Higher downtime, due to unexpected breakdowns or frequent replacements.

- Safety risks, since blunt or damaged blades increase the chance of accidents.

Cost Savings Through Preventative Maintenance

Routine blade sharpening, inspection, and replacement significantly reduce operating costs. A well-maintained blade not only lasts longer but also ensures that machines operate at optimal speeds, reducing strain on equipment. For poultry processors, this translates into higher throughput, less downtime, and improved profitability.

Meeting Food Safety Standards

With strict regulations in place, particularly in export-driven markets, hygiene is paramount. Dull or damaged blades can harbor bacteria or cause uneven cuts that complicate further processing. Regular blade maintenance is essential in maintaining compliance and protecting consumer safety.

Partnering with Experts

Outsourcing blade maintenance to trusted specialists ensures consistency and reduces internal workload. Machine Knives Australia (MKA) offers precision re-sharpening services and custom blade solutions tailored to poultry processing needs, helping businesses extend blade life while improving performance.

In a competitive and highly regulated industry, poultry processors cannot afford to overlook blade maintenance. By prioritising sharp, reliable, and hygienic machine knives, businesses can safeguard efficiency, product quality, and food safety—giving them a crucial edge in today’s marketplace.