Recycling and Granulator Blades: Why Maintenance Matters More Than Ever

Why Maintenance Matters More Than Ever for Recycling and Granulator Blades

The recycling industry is under increasing pressure to process higher volumes of material with greater efficiency. From plastics and rubber to electronic waste and scrap metal, every stage of the process relies on granulator blades to break down materials cleanly and consistently. But just like in food or meat processing, blade quality and maintenance make all the difference.

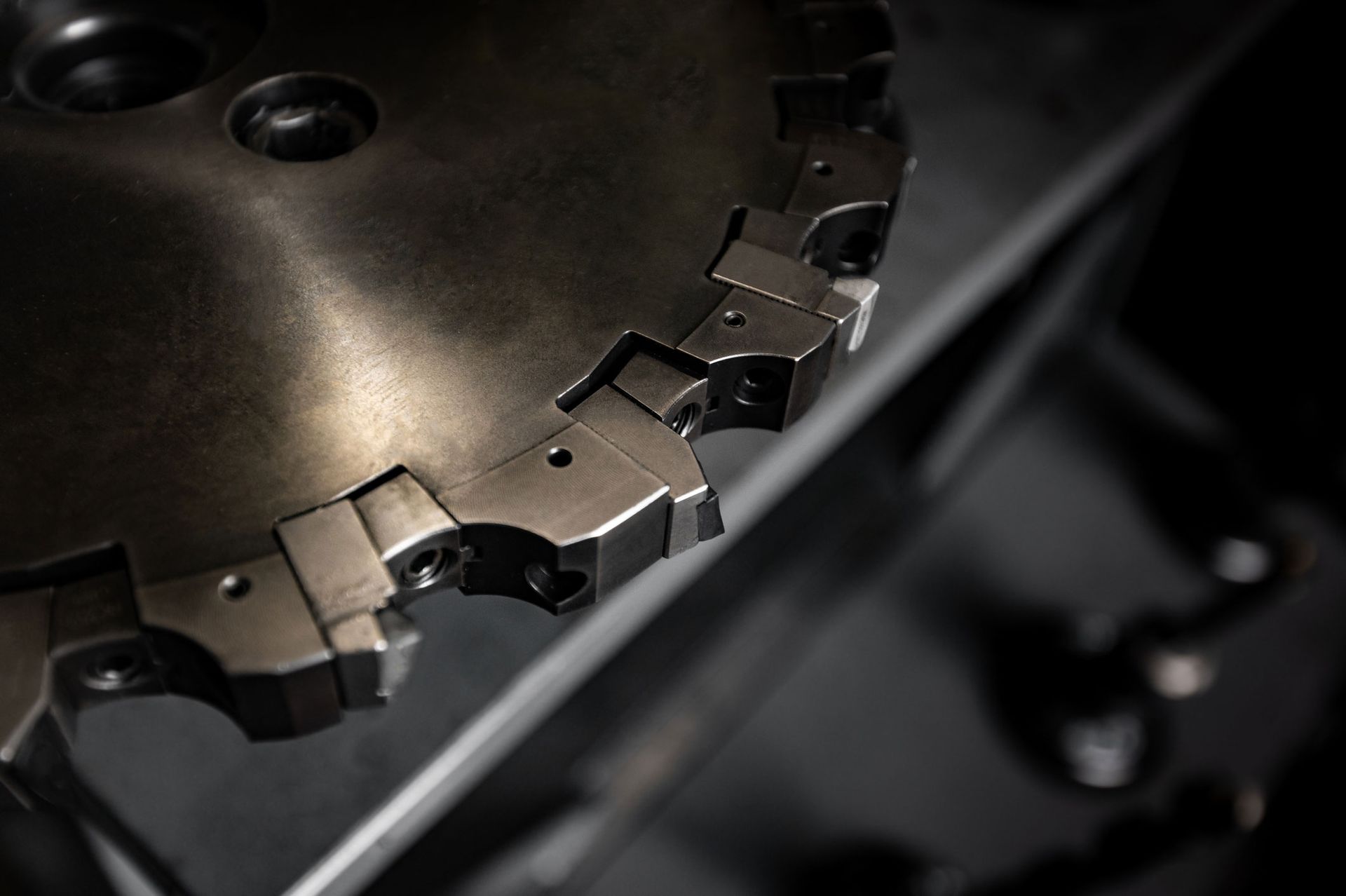

The Role of Granulator Blades in Recycling

Granulator blades are the workhorses of recycling plants. Their sharpness and durability directly impact throughput, particle size consistency, and equipment longevity. A dull or damaged blade can:

- Reduce cutting efficiency and increase energy consumption.

- Cause uneven particle sizing, making further processing more difficult.

- Place additional strain on machinery, leading to premature wear and breakdowns.

Why Regular Maintenance is Essential

Routine sharpening and replacement ensure that blades operate at their full potential. Well-maintained blades:

- Improve efficiency by cutting cleaner and faster.

- Reduce downtime caused by blade-related breakdowns.

- Extend equipment life, protecting your investment.

- Lower operating costs by reducing wasted energy and material.

Supporting Sustainability Goals

Recycling is all about sustainability, and effective blade maintenance contributes directly to those goals. By ensuring cleaner, more efficient cuts, companies can process higher volumes with less waste—helping to close the loop in the circular economy.

Partnering With Specialists

At Machine Knives Australia (MKA), we design, manufacture, and maintain granulator blades for recycling applications. With precision re-sharpening services and locally made replacements, we help recyclers stay productive, efficient, and sustainable.

As the recycling industry grows, so too does the demand for high-performing machine blades. Regular maintenance of granulator blades isn’t just a cost-saving measure—it’s a cornerstone of sustainable, efficient recycling operations.