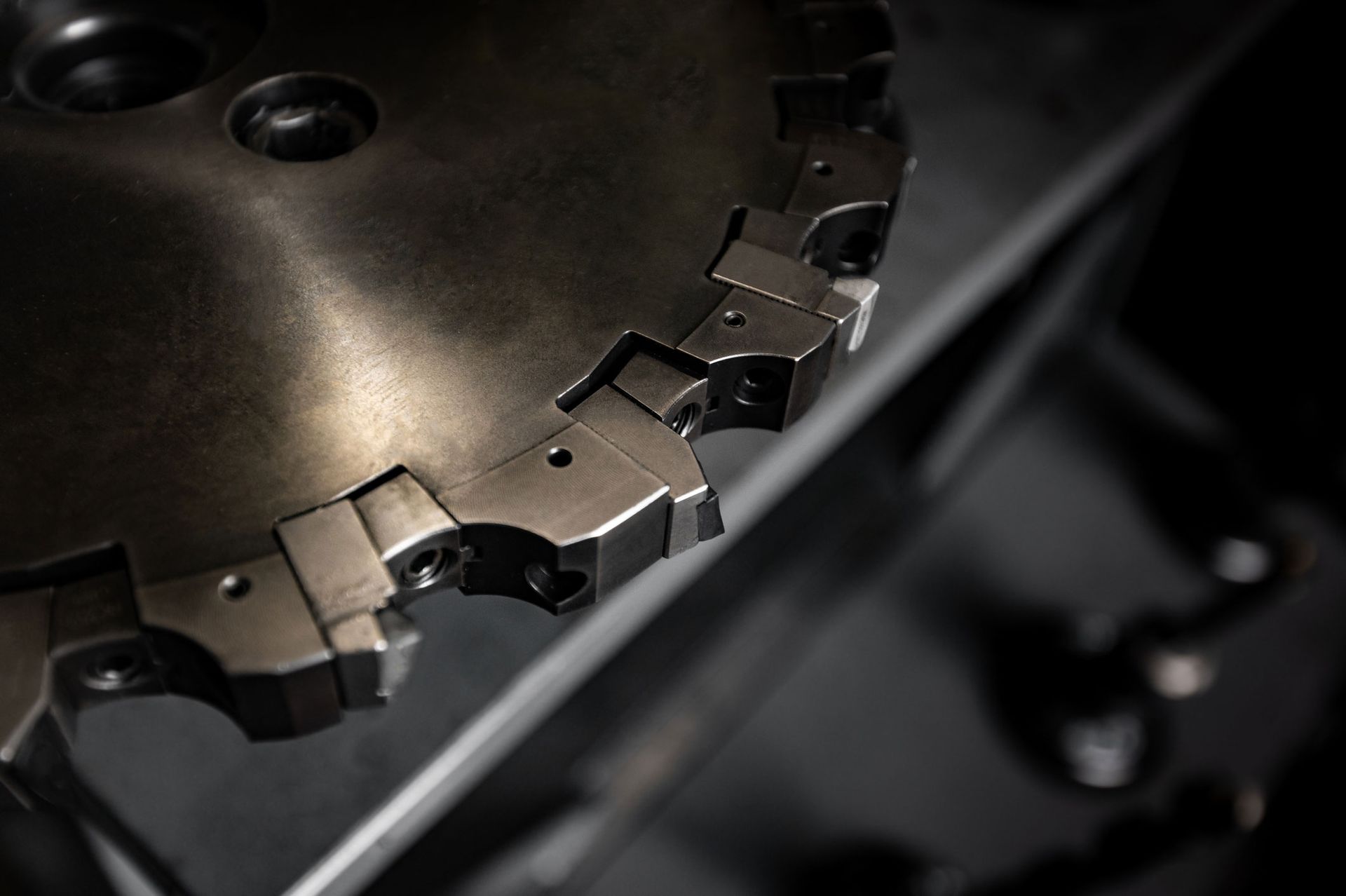

How Blade Efficiency Drives Productivity in Meat Processing Plants

3 August 2025

In meat processing plants, blade efficiency isn’t just about sharpness—it’s about seamless integration of knife performance, line speed, and product quality. Every unscheduled blade change or sub-optimal cut can cost hundreds in lost downtime, increased trim, and potential food-safety issues. This article explores the multifaceted impact of blade efficiency and offers actionable strategies to drive plant productivity.

Impact on Throughput & Yield

- Reduced downtime: Sharp, well-maintained blades minimize line stoppages for emergency changes.

- Trim waste reduction: Consistent, clean cuts preserve more usable meat, improving yield by up to 3–5 %.

- Line balancing: Optimized cutting rates allow downstream processes (portioning, packaging) to operate at design capacity.

Meat Quality & Food Safety

- Clean slicing: Efficient blades produce smooth surfaces that inhibit bacterial harborage, supporting HACCP protocols.

- Temperature control: Minimizing frictional heat at the blade interface preserves product integrity and shelf life.

Cost Savings & ROI

- Blade life extension: Proper maintenance can double service intervals, cutting sharpening fees and replacement costs in half.

- Energy efficiency: Well-tuned cutting systems draw less power, reducing utility bills over high-volume runs.

Performance Metrics & Monitoring

- Key indicators: Track metrics such as cuts per sharpening, average cut time, and downtime events per shift.

- Continuous improvement: Use SPC (Statistical Process Control) charts to identify trends and trigger proactive maintenance.

Conclusion

Optimising blade efficiency in meat processing plants delivers substantial gains across throughput, yield, safety, and cost. By measuring performance, standardizing maintenance, and embracing automation, processors can turn blades into strategic assets that drive continuous productivity improvements.

Industrial blade coatings play a pivotal role in elevating knife performance across paper, film, food processing, and metalworking lines. By applying specialized surface treatments, manufacturers unlock gains in wear resistance, friction reduction, and corrosion protection—translating into longer service intervals, cleaner cuts, and lower total cost of ownership.